From the batch plant to the warehouse

Glass production is not possible anymore without networked and sophisticated automation solutions.

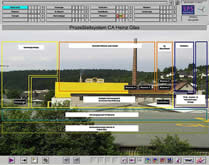

Schlemmer Prozess Systeme GmbH is working for many years in the glass industry and has therefore gained extensive experience it in wide areas of automation engineering. The primary aims at the planning and construction of automation solutions are reduction of production costs per piece on the one hand and on the other hand a concept of an uniform, general automation with standardized components. This results in the minimization of costs for spare parts, maintenance and training substantially. These demands can be fulfilled by Siemens components very well. We use the process control system Simatic PCS7 for large-scale installations in combination with particularly, self-developed faceplate technology for the glass industry. These are individually adapted to the individual customer requirements by us, as a basis for uniform automation solution for the complete factory automation.

For smaller plants we use the WinCC visualization package or the Protool package for small plants to carry out cost reduction. In the area of the batch mixture we use controllers of the series SIWAREX U or M in connection with S7 400 controller and decentralized ET200 periphery with Profibus or Ethernet interface. In the melting area, the ET200 modules are also used together with the S7 400 and S7 300 controllers. For an exact controlling of the combustion air we take frequency converters of the series Micromaster with Profibus interface. The plunger control system is realized with the Simatic S7 317 T CPU. On the machines and handing over units Simodrive or Sinumerik drive components are used. Different OP´s (operation panel) and TP´s (touch panel) are used as display and operator unit directly at the machinery. By using a decentralized construction with ET200 modules in connection with OSM (optical switch module), OLM (optical link module) and optical fibre the reduction of the wiring effort is substantially, which leads to an enormous reduction of costs by installation, maintenance and operation of the plant. A high availability of the plant is guaranteed by means of remote diagnosis and remote project engineering. Also the maintenance effort and the fault diagnosis time will be reduced to a minimum.

It would be a pleasure for Schlemmer Prozess Systeme GmbH to support you by the development of an automation concept according to your requests. A support during the whole life cycle of the plant, from the planning up to the start-up and the daily production is a matter of course.